The ST Engineering Retrofitted Electric Bus is the product of an electric bus conversion project undertaken by ST Engineering and Linkker on an existing MAN A22 (Euro V) bus. Initiated by the Land Transport Authority (LTA) in 2017, the project is a proof-of-concept to determine the feasibility of converting existing diesel buses to electric buses.

Only one unit exists, registered SG3100M. It is fitted with the Linkker LinkDrive conversion kit. A similar electric driveline was fitted to the 20 Linkker LM312 buses procured by LTA.

As for the MAN A22 platform, a total of 734 MAN A22 buses were brought in by SMRT Buses between 2010 and 2016, built to Euro V specifications. All units are bodied by Gemilang Coachworks of Malaysia. Another MAN A22 concept bus, the 3-door MAN Lion’s City SD Concept Bus (now LTA Smart Bus), was also a project undertaken by ST Engineering.

On 5 October 2021, the bus made its revenue service debut on Service 176, operated by SMRT Buses.

Main article: MAN A22

Background:

See also: MAN A22 electric bus conversion project

ST Engineering’s 2017 Annual Report first revealed that the company was awarded an LTA tender to retrofit a single-deck electric MAN bus as a proof-of-concept. The tender is believed to be a closed tender, with LTA not making any references to the tender within its annual reports published in that period.

The retrofit project was done in cooperation with Finnish electric bus manufacturer Linkker, who ST Engineering worked with to bring its electric bus technologies into the Singapore market. ST Engineering is currently an authorised distributor of Linkker right-hand drive electric buses in the Asia-Pacific region, with a partnership inked in 2017 and Linkker cited as an “Original Equipment Manufacturer (OEM)”.

As for the bus, SMB3075A was selected for the conversion. The bus is a former Euro V MAN NL323F bus (Chassis no.: WMAA22ZZXD7001880) bodied with the MAN Lion’s City Hybrid bodywork assembled by Gemilang Coachworks. First registered to SMRT Buses on 2 September 2013, it was first laid up from October 2017 to October 2018, which indicated that the bus would be taken out of service for a prolonged period of time (during which it is exempted from road tax). It bore SMRT’s beige livery at launch, before being repainted to SMRT’s pixel livery.

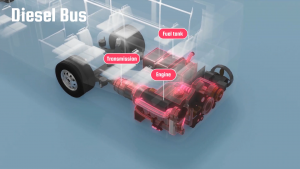

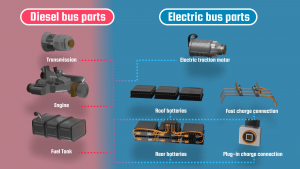

SMB3075A was shipped from Singapore to Turku (Finland) for the modification work, where it was retrofitted with the Linkker LinkDrive retrofit kit, a conversion kit based off Linkker’s own electric drivetrain. The main subsystems of the conversion kit are the traction system, battery system, power distribution unit, vehicle control system, charging connectivity system and driver’s workplace upgrade. Linkker conversion kits are also made for other bus types.

Apart from this project, ST Engineering (Land Systems) also worked with Linkker on various projects such as the STE-Linkker Autonomous Electric Bus, and the fulfillment of 20 Linkker LM312 pantograph-charged buses procured by LTA, which entered revenue service in 2021. The company was one of three successful tenderers, the others being BYD and Yutong, who delivered a combined 60 electric buses between 2019 and 2020.

ST Engineering Retrofitted Electric Bus

The sole ST Engineering Retrofitted Electric Bus (formerly SMB3075A) was re-registered as SG3100M to SMRT Buses Ltd (former operator of SMB3075A) some time in October/November 2019, under a non-user lay-up status. Throughout this period, the bus was spotted in storage at various places, such as a warehouse facility at Tuas South leased by Pacific Logistics Group, as well as at the ST Engineering Land Systems car park at Corporation Road.

The bus was taken out of lay-up on 29 July 2021 and continues to be registered under SMRT Buses. It was deployed on revenue service from 5 October 2021.

Electric drivetrain components are supplied by Linkker (branded as LinkDrive).

| Basic Technical Specifications | |

| Dimensions | Length 12.0 m; Width 2.55 m; Height 3.34 m. |

| Driveline | Linkker LinkDrive electric driveline |

| Electric Machine | Danfoss Editron EM-PMI375-T800-1600 Synchronous Reluctance assisted Permanent Magnet Motor (dual inverter) Continuous power/torque of 139 kW / 828 Nm Maximum power/torque of 231 kW / 2100 Nm |

| Battery | Lithium Iron Phosphate batteries (177.5 kWh) Opportunity charging via inverted pantograph (Oppcharge) with secondary CCS2 plug-in charging capability Up to 450 kW DC charging input Up to 130 km range, depending on operating scenarios |

| Bodywork | MAN Lion’s City Hybrid (Built under license by Gemilang Coachworks) EcoRange aluminium bus body, full-low-floor layout |

| EDS | Mobitec MobiLED, orange LED matrix design Mobitec MobiMASTER ICU 402 controller |

| Passenger Capacity | 35 seating + 56 standing = 91 total |

| Additional Specifications | Vogelsitze System 750/3 seats Masats doors Onboard Telemetry System Fire suppression system in battery compartments Stroller Restraint System TNT Surveillance Front Alert Camera & Side Camera |

It is noted that the retrofitted electric bus has opted for Lithium Iron Phosphate (LFP) batteries, which differ from two existing Lithium-ion battery options offered with Linkker buses (LTO and NMC batteries).

Omitting detailed comparisons between the three, LFP batteries are relatively cheaper, less toxic, and typically last longer as compared to other forms of Lithium-ion batteries. LFP batteries have also been widely adopted for electric buses, with the world’s leading electric bus manufacturers by sales volume (Yutong, BYD and Zhongtong) opting for LFP batteries.

Layout

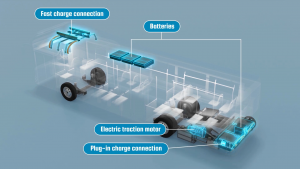

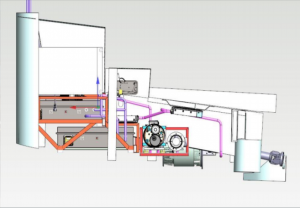

From illustrations published by Linkker and ST Engineering, it can be seen that a single longitudinally-mounted Traction motor is mounted in place of the transmission, located at the rear left side of the bus. Lithium-ion Batteries, Battery Management System (BMS), and Motor Control Unit are all mounted in the rear engine bay. The motor is also liquid-cooled, as can be seen from the pink coolant lines (water-propylene glycol) in the side profile diagram. These observations correspond with pictures published by the media.

The roof of the bus houses the air-conditioning unit and charging rails, which are compatible with the OppCharge opportunity charging interface. An inverted pantograph is used to quickly charge the bus during revenue service.

In total, the Retrofitted Electric Bus houses nine battery banks, with six units in the former engine compartment, and three more units on the roof.

Performance

According to specifications released by LTA, a 10-minute charge stores up to 75kWh of energy in the bus’ batteries, which is sufficient for up to 48km of range. Specification sheets indicate a full recharge time of 30 minutes, and up to 130 km of range on a full charge, depending on operating scenarios.

As part of the retrofitting works, the centre pole at the entrance has been removed to allow easier access for passengers travelling with open strollers.

Opportunity charging

Based around the concept of Opportunity charging, the ST Engineering Retrofitted Electric Bus is charged at the terminus of a bus route, where charging points (typically overhead charging) are erected. The bus is sufficiently recharged in a short amount of time (usually several minutes) before the bus continues on its next trip.

With fewer batteries required per bus, its advantages translate to a more spacious bus interior, lower environmental cost of battery production, and lower electricity consumption through reduced vehicle weight. Its disadvantages include the lack of deployment flexibility (on non-infrastructure-equipped routes) and the possible impact on bus operations should a charging station break down, and some redundancy is thus required, such as installing multiple chargers at terminating points.

Currently, efforts are focused on expanding the use of opportunity charging on suitable routes and the adoption of similar charging infrastructure between bus manufacturers, allowing multiple bus models to use the same charger.

The Opportunity Charging approach is favoured by European bus manufacturers. Conventional, depot-charged buses carry a large number of batteries on every bus to achieve sufficient operating range over a day’s worth of revenue service, and is the approach preferred by Chinese bus manufacturers.

Overhead pantograph

The ST Engineering Retrofitted Electric Bus will be charged via overheard pantograph, based on the opportunity charging (OppCharge) platform.

OppCharge is an open and competition-neutral interface seeking to accelerate the adoption of electric buses by being compatible with multiple bus manufacturers, hence offering operators choice and flexibility of buses without the need to modify existing charging infrastructure. These overhead pylon chargers with extendable pantographs are usually installed at the end stops of bus routes, allowing buses to quickly receive a full charge in-between trips.

Charging is fully automatic and secured by a two-way WiFi communication sequence. The driver gets a clear indication in order to stop within the specified ± 200 mm from the reference point. The charging sequence is started by activating the parking brake, and the driver can interrupt it at any time.

Swiss-Swedish engineering group ABB supplied four 450 kW chargers with installation, civil works, project management and commissioning. These chargers would allow the electric buses to be quickly recharged in less than ten minutes at key bus interchanges with an automated rooftop connection.

A similar overhead charger was installed at Cleantech Park in support of the NTU-LTA-Volvo Autonomous Bus Trial. The Volvo 7900 Electric bus participating in the trial is OppCharge-compatible and is recharged with the ABB HVC 300P fast-charge system, which delivers 300 kW DC power.

Two overhead pantograph chargers were each installed at Bukit Panjang Integrated Transport Hub and Bedok Integrated Transport Hub.

Gallery

External Links & References:

- LTA to Deploy Electric Buses from Early 2020 – LTA [Accessed 24 Jun 2020]

- 陆路交通管理局:60辆新电动巴士 明年初投入服务 – 8World [Accessed 24 Jun 2020]

- Accelerating Emission Reductions: Linkker Diesel to Electric Bus Conversion Kits – LinkkerBus [Accessed 22 Aug 2020]

Back to Bus Models

Back to Bus Articles