| ST Engineering Electric Bus | |

|

Clik here to view.  |

|

| Manufacturer | ST Engineering Land Systems |

| Bodywork | Gemilang Coachworks Sdn Bhd |

| Years in operation | 2020— |

| Operators | TBA |

| Technical Data | |

| Length | 12 metre |

| Powertrain | Linkker LinkDrive |

| Accessibility | Low Floor |

| Emission Standard | Zero tailpipe emissions |

The ST Engineering Electric Bus (final name TBC) is a fully electric, low-floor single-deck city bus offered by ST Engineering Land Systems. Primary contractors include Finnish electric bus manufacturer Linkker for the electric drivetrain, and Malaysian bodybuilder Gemilang Coachworks for the bodywork.

20 units of the ST Engineering Electric Bus bus were procured by the Land Transport Authority in 2018 as part of efforts to build a more environmentally friendly public bus fleet. In total, 60 electric buses were procured from three separate manufacturers at a total sum of S$50.64 million. These buses are also the first public buses in Singapore to be charged via overhead pantographs at bus interchanges.

Background

ST Engineering is a Singapore-based integrated engineering group dealing in the aerospace, electronics, land systems and marine sectors; primarily engaging in defence applications. The company’s Land Systems division (formerly ST Kinetics) is established in the local bus industry as the local distributor for MAN buses (MAN A22, MAN A24 and MAN A95), of which many entered service in Singapore since 2011.

The company has also produced a 3-door concept single-deck bus and a 3-door concept double-deck bus, both of which commenced revenue service trials in 2017, and had refitted an existing diesel bus to an electric bus as a proof-of-concept. ST Engineering also secured an LTA contract for 3-door Euro 6 double-deck buses and is working with LTA to develop and trial fully-autonomous buses in the future.

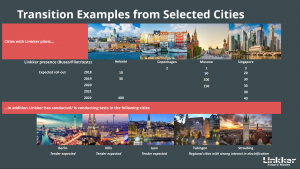

For the ST Engineering Electric Bus, electric drivetrain components are most like procured from Linkker, an electric bus manufacturer from Finland. The partnership was indicated in ST Engineering’s 2017 Annual Report, referred to as a “partnership with an Original Equipment Manufacturer (OEM) for electric buses to distribute electric buses in right-hand drive countries in Asia Pacific, including Singapore, Australia, Hong Kong, Indonesia, Malaysia, New Zealand and Thailand”.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Linkker had previously tested its buses domestically (in Helsinki, Espoo, Turku) and overseas in Copenhagen and Moscow. It is understood that their electric motors and inverter are procured from Danfoss, a Denmark-based engineering group.

Finally, the ST Engineering’s 20 single-deck electric buses bear a stylish bodywork design similar to its Autonomous Electric Bus. Body panels are built and assembled by bodybuilder Gemilang Coachworks of Malaysia.

Find out more about Electric Buses in Singapore here.

ST Engineering Electric Bus

Twenty units of the ST Engineering Electric Bus for the Singapore market are bodied by Gemilang Coachworks in Malaysia, with electric drivetrain components supplied by Linkker (branded as LinkDrive).

These buses are based off the Linkker 12+ city bus, and bears strong similarities with the STROBO Series 12 Bus Autonomous Electric Bus first unveiled in October 2018, bearing the same bodywork design. Like the STROBO Series 12, these buses are OppCharge-compatible, fully-low-floor and equipped with three doors for more efficient passenger movement.

All technical specifications are indicative and based off brochures for the Linkker 12+ electric bus. Actual specifications are to be confirmed.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

| Basic Technical Specifications (TBC) | |

| Driveline | Linkker LinkDrive electric driveline |

| Electric Motor | 180 kW Permanent Magnet Motor, max torque 7.824 Nm at rear wheels (TBC) Supplied by Danfoss Editron (model unknown) |

| Battery | 63.5kWh Lithium–titanate oxide batteries (TBC) Charged via an overhead pantograph (450 kW) at bus interchanges, with secondary plug-in charging capability 30–50 km range, depending on operating scenarios |

| Bodywork | Gemilang Coachworks bodywork, designed by ST Engineering ‘EcoRange’ aluminium bus body, full-low-floor layout with 3 doors |

| Electronic Display Sign (EDS) | Mobitec MobiLED Ultima Amber EDS (Front) Gorba imotion LED.e TOPSMART EDS (Side & Rear) Orange LED Matrix design |

| PIDS | LAWO INFOtainment Passenger Information Display System (PIDS) Interior-facing unit and exterior-facing unit Interior & Exterior Speakers |

| Passenger Capacity | TBC |

| Additional Specifications | ST Engineering DriveSafe Advanced Driver Assistance System TNT Surveillance Golden Eye Anti-Fatigue System Eberspächer Sütrak AC136 G4 AE electric air-conditioning system Masats door systems USB Charging Ports Vogelsitze System 750/3 seats Rooftop charging rails for inverted pantograph charging (Oppcharge) |

See Also: ST Engineering STROBO Series 12 Bus – Autonomous Electric Bus

Opportunity charging

Based around the concept of Opportunity charging, the ST Engineering Electric Bus is charged at the terminus of a bus route, where charging points (typically overhead charging) are erected. The bus is sufficiently recharged in short amount of time (usually several minutes) before the bus continues on its next trip.

Clik here to view.

With fewer batteries required per bus, its advantages translate to a more spacious bus interior, lower environmental cost of battery production, and lower electricity consumption through reduced vehicle weight. Its disadvantages include the lack of deployment flexibility (on non-infrastructure-equipped routes) and the possible impact on bus operations should a charging station break down, and some redundancy is thus required, such as installing multiple chargers at terminating points.

Currently, efforts are focused on expanding the use of opportunity charging on suitable routes and the adoption of similar charging infrastructure between bus manufacturers, allowing multiple bus models to use the same charger.

The Opportunity Charging approach is favoured by European bus manufacturers. Conventional, depot-charged buses carry a large number of batteries on every bus to achieve sufficient operating range over a day’s worth of revenue service, and is the approach preferred by Chinese bus manufacturers.

Overhead pantograph

The ST Engineering Electric Buses are charged via overheard pantograph, based on the opportunity charging (OppCharge) platform.

Clik here to view.

OppCharge is an open and competition-neutral interface seeking to accelerate the adoption of electric buses by being compatible with multiple bus manufacturers, hence offering operators choice and flexibility of buses without the need to modify existing charging infrastructure. These overhead pylon chargers with extendable pantographs are usually installed at the end stops of bus routes, allowing buses to quickly receive a full charge in-between trips.

Charging is fully automatic and secured by a two-way WiFi communication sequence. The driver gets a clear indication in order to stop within the specified ± 200 mm from the reference point. The charging sequence is started by activating the parking brake, and the driver can interrupt it at any time.

Swiss-Swedish engineering group ABB supplied four 450 kW chargers with installation, civil works, project management and commissioning. These chargers would allow the electric buses to be quickly recharged in less than ten minutes at key bus interchanges with an automated rooftop connection.

A similar overhead charger was installed at Cleantech Park in support of the NTU-LTA-Volvo Autonomous Bus Trial. The Volvo 7900 Electric bus participating in the trial is OppCharge-compatible and is recharged with the ABB HVC 300P fast-charge system, which delivers 300 kW DC power.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Two overhead pantograph chargers were each installed at Bukit Panjang Integrated Transport Hub and Bedok Integrated Transport Hub.

See also: Installation of overhead bus chargers at Bedok and Bukit Panjang

Gallery:

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

Image may be NSFW.

Image may be NSFW.Clik here to view.

External Links & References:

- LTA Awards Contract for 60 Electric Buses to Three Tenderers – LTA

- Linkker – business from Finnish electric bus competences [PDF]

- EDITRON: Danfoss Power Solutions journey to electrification [PDF]

Back to Bus Models

Back to Bus Articles